Bubble foil is produced under BUFO® barrier brand. Bubble foil is made of low density polyethylene. It is a modern, clean, easy to use and flexible packaging material. BUFO barrier foil is suitable for many packaging applications - from surface protection and interleaving up to creation of protective cushions and empty space packing.

BUFO® barrier bubble foil

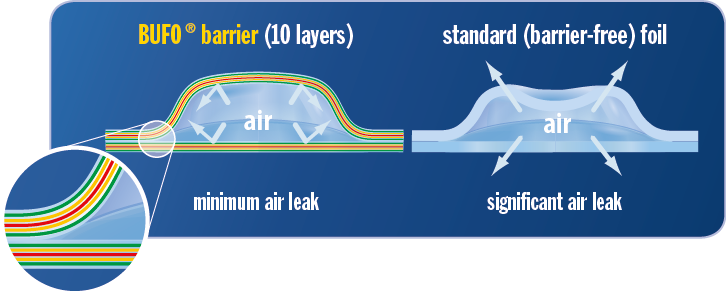

BUFO® barrier bubble wrap is produced by the latest available technology. The foil consists of ten microlayers, and the middle layer consists of a special nano-barrier which prevents air leakage even during prolonged foil load. We can produce bubble foil with reduced thickness and with excellent quality properties.Because of its qualities BUFO barrier bubble foil was awarded the title of Packaging of the Year 2012.

The video of the new product line can be viewed here

Main advantages of BUFO® barrier bubble foil:

- high load resistance

- high strength and flexibility

- long-term alveolar stability

- low weight

- decrease of packaging costs

- more environmentally friendly

- easily reusable

- protective pads for packaging of a wide range of products,

- scratch protection

- protection against damage during transport or storage

- packaging of furniture, porcelain, glassware, electronic components and spare parts,

- large bubbles are specifically designed for the filling of vacant space and light pads are for fragile products, or even moderately heavy and heavier items (laboratory glassware, electronic instruments, industrial spare parts)

A range of bubble wraps

TART produces a wide range of bubble wraps - bubble films with bubbles of various sizes, light bubble wraps and above-standard wraps. We can laminate all bubble wraps (e.g. with aluminium, paper, polyethylene), print on them or improve their protective properties with various additives (anti-corrosive, antistatic, etc.).

Bubble wrap BUFO M

- bubble diameter 10 mm, height 4 mm

- roll width max. 2 m

- foil on the roll available with perforation for easy tearing (min spacing 25 cm)

- the most common type of bubble wrap

- for packaging smaller products placed in a box

- for packaging furniture, appliances, components, etc.

- suitable for packaging mass produced clothing - sacks, bags or blanks

Bubble wrap BUFO L - NEW

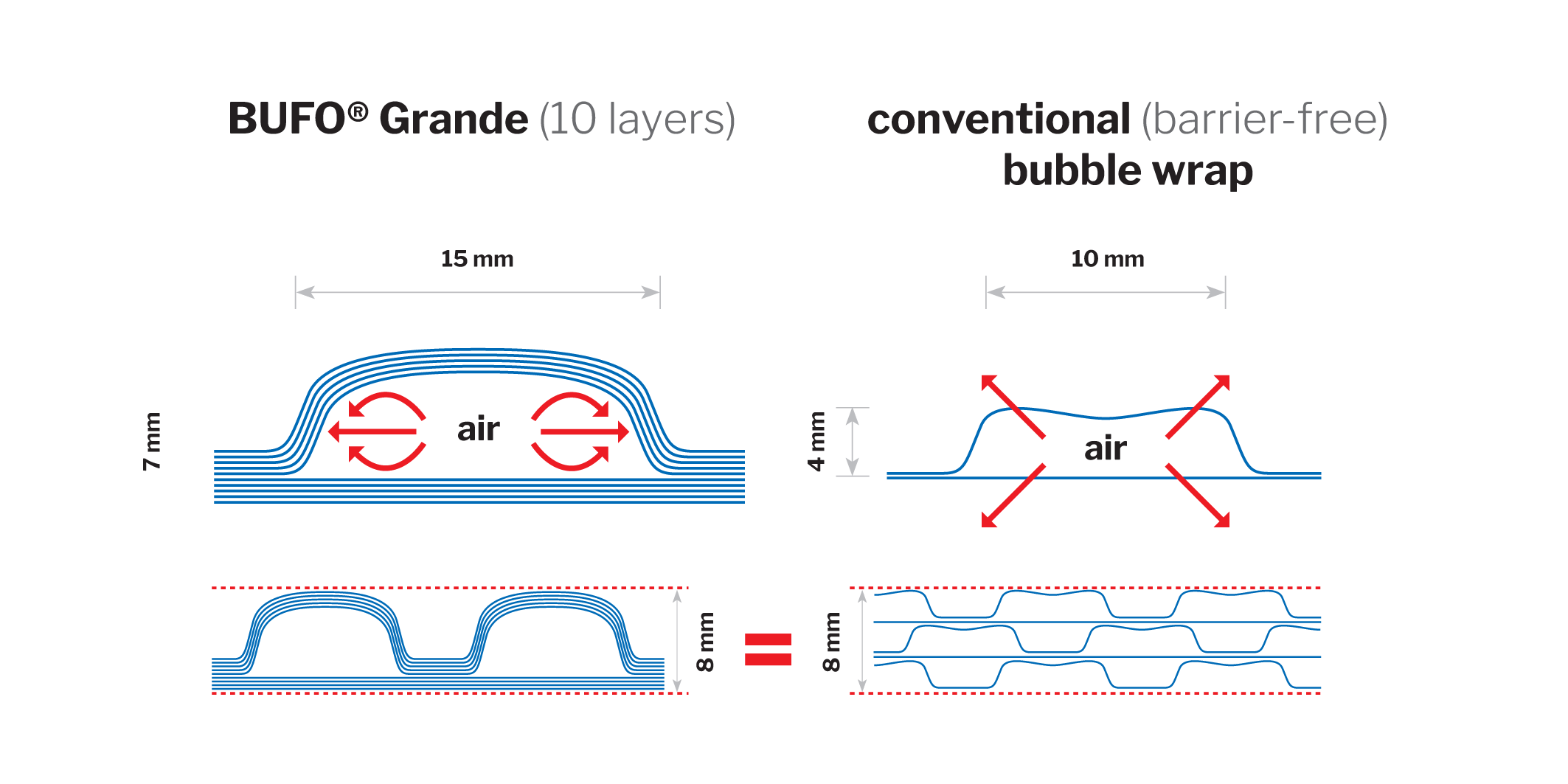

BUFO Grande is a specially developed bubble wrap designed mostly for the packaging of on-line shops parcels. It is suitable both for product protection and filling of empty space in boxes and as packaging material for large products (electrical appliances, etc.). Its advantage is that it has three times as much air as compared to conventional bubble wrap. The BUFO Grande bubble wrap thus consumes three times less and saves you the cost and time it takes to pack and also the environment.

- bubble diameter 15 mm, height 8 mm

- roll width max. 2 m

- foil on the roll available with perforation for easy tearing (min spacing 25 cm)

- modern type of bubble wrap

- excellent for protection and padding of parcels for e-shops or packing whole products

- significant saving in packaging material (compared to the normal bubble wrap)

- ecological solution

Bubble wrap BUFO XL

- bubble diameter 25 mm, height 15 mm

- roll width max. 2 m

- excellent padding material

- excellent thermal insulation properties

Three-layer / four-layer design (lamination) of bubble wrap BUFO barrier

By laminating individual types of bubble wrap a new material is produced, the mechanical and physical properties of which are further emphasized by the type of material used for lamination. We can laminate bubble wrap on the top or bottom layer, or on both sides.

BUFO + aluminium / metallized foil

- Bubble foil for overseas export packaging, building heat-reflective foil.

BUFO + HDPE / LDPE

- Protective packaging of heavy articles, furniture, automotive parts, etc. Extreme protection.

BUFO + paper

- Protective packaging of heavy articles, furniture, automotive parts, moving etc. Non-transparent extreme protection.

BUFO + foamed PE

- Very fragile goods, increased protection against scratches.

Special bubble foil design

BUFO barrier bubble foil can also be made with special features:

- BUFO antistatic – packaging of electrical equipment and accessories

- BUFO anti-corrosion - corrosion protection

- BUFO biodegradable

BUFO Envira® compostable bubble wrap foil

TART is the world's first manufacturer of 100% compostable bubble wrap foil. BUFO Envira® foil is made from ecological bioplast and, after the end of its life, can be broken down by bacteria found in compost into biomass, water and CO2. This process of biological degradation does not put extra strain on the environment.

When properly stored, the BUFO Envira® foil keeps its excellent mechanical properties for an unexpectedly long period of time. This material surpasses conventional bubble wraps made from conventional plastics (LDPE) in terms of resistance against compression and bubble burst. BUFO Envira® bubble wrap foil has excellent protective properties and is a great ecological option for protecting your goods from damage or scratches.

When properly stored, the BUFO Envira® foil keeps its excellent mechanical properties for an unexpectedly long period of time. This material surpasses conventional bubble wraps made from conventional plastics (LDPE) in terms of resistance against compression and bubble burst. BUFO Envira® bubble wrap foil has excellent protective properties and is a great ecological option for protecting your goods from damage or scratches.

BUFO Envira® Features:

- bubble diameter 10 mm, height 4 mm

- roll width max. 1 m

- also suitable for manufacturers of clothing - bags, sacks or sheets

- Foil on the roll available with perforation for easy tearing (min spacing 25 cm)

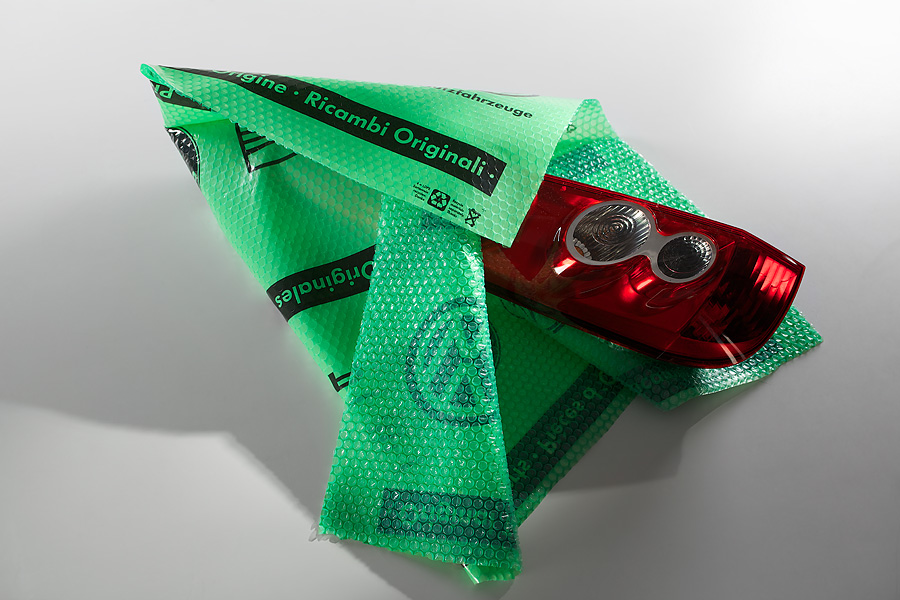

- colour: green colour

- 100% compostable and really ecological

- complies to DIN EN 13 432 (standard for compostable packaging with a degradation of up to 90 days in industrial compost environment)

Printed and coloured bubble foil BUFO® barrier

Advantages of printed bubble foil:

- distinguishing

- advertising on the packaging

- possibility of technical communications directly on foil

Printing options

- 1 colour – e.g. recycling symbol, handling characteristics

- 1-6 colours - endless printing (max. roll width 10 cm)

- 1-6 colours – all over print

Current common colours are red (usually produced as antistatic), black, blue, yellow.

Bags and sheets of bubble foil

- suitable for packing of products of the same size (calculators, phones, cameras),

- possibility to pack even larger products (chairs, furniture components),

- size of bag is always adapted to the size of article to be packed and the customer saves time and costs in preparation of packaging materials as well as the packaging itself,

- antistatic bubble foil can be used for packaging of electronic devices that are sensitive to static electricity.

Advantages of bubble foil bags:

- precisely defined packaging costs,

- significant increase in work productivity,

- user-friendly package,

- reduced consumption of other packaging materials (adhesive tapes, fixatives, etc.).

Advantages of bubble foil sheets:

- packaging time saving

- easy-to-control consumption of packaging material

- packaging material savings

- simple storage and handling

Bubble Envelopes

Bubble foil lined envelopes are made with the top layer of white paper (brown option).

Advantages of bubble envelopes:

• protects the contents against impact

• light weight

• sealing of envelopes is achieved by adhesive flap with repeatable closing

• paper and bubble polyethylene are recyclable

Internal dimensions of supplied bubble envelopes (width x length in mm)

120x215, 150x215, 180x265, 220x265, 220x340, 230x340, 270x360, 300x445, 350x470

Horizontal Manual Bubble Foil Cutting Machine

- used for cutting bubble foil rolls of different lengths,

- easy fabrication of sheets of various sizes, which guarantee smooth edges in both directions,

- suitable for cutting rolls with a length of 150m and a width of 150 cm,

- cutting of plastics, paper, cardboard,

- cutting in both directions of cutting blade movement,

- cutting knife blade is easily replaceable,

- three types of knives for different types of material to be cut.

Simple and stable structure equipped with braked wheels allows for easy handling and placement of the cutting machine on the most convenient place in the manufacturing process.

Send your inquiry to demand@tart.cz