When packing products into boxes we offer special cushioning inserts and fillings which protect the packaged products against shocks and damage, especially during transport and handling. The Fill-Air, NewAir and RapidFill systems create air cushions of various shapes and sizes. Korrvu fixation membranes consist of a film with high elongation, which is glued to the cardboard with a special glue. The fragile product is securely fixed with the film - an anti-slip elastic membrane - directly to the cardboard. Products can also be protected with creased paper from FasFil or ProPad systems.

Fillings and Fixations

Paper fillings and cushioning inserts

Paper is a great protective material when packing shipments into cardboard. Just crease it properly in our FasFil® and ProPad® systems. The created paper fillings and cushioning inserts then perfectly protect the packaged product, prevent its movement in the box and fill the empty space. Paper fillings and cushioning inserts are also suitable for packaging heavy products.

FasFil® Systems

FasFil® systems for production of paper fillings are powerful, reliable and very durable. Working with these systems is very easy and intuitive. In addition, it is an environmentally friendly solution - the pads are created from 100% recycled folded paper, which can be further recycled after use.

FasFil® 1500

This system produces paper fillings the fastest of all. It is operated using a control panel or a foot pedal. It uses folded paper for the production of fillings. The width of the input paper is 38 cm. It is suitable for small and medium shipments.

Benefits of FasFil® 1500 system

- production at speeds of up to 119 running metres per minute

- large material container (allows you to produce several kilometres of fillings)

- simple and fast material change

- saving space when storing material

- various paper weights (50 g/m2 for lighter things, 72 g/m2 for heavier products)

- Adjustable height and system rotation can be adapted to any packaging operation

- can be placed on a workbench or stand on its own

FasFil® Jet

This system produces large paper fillings, suitable for larger shipments. The width of the input paper is 76 cm. It is operated using a control panel or a foot pedal. Folded paper is used to manufacture fillings.

Benefits of FasFil® Jet

- production at speeds of up to 1,07 running metres per minute

- large material tray (allows you to make several kilometres of fillings)

- manual or programmed production modes

- simple and fast material change

- saving space when storing material

- various paper weights (50 g/m2 for lighter things, 72 g/m2 for heavier products)

- Adjustable height and system rotation can be adapted to any packaging operation

- can be placed on a workbench or stand on its own

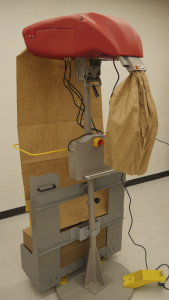

ProPad®

This system produces large paper fillings, suitable for larger shipments. The width of the input paper is 74 cm. It is operated by using a control panel or a foot pedal. The system produces padding from rolls or folded paper.

Advantages of ProPad® system

- production at speeds of up to 150 fillings per minute

- works in several possible modes -manual, automatic repetition and programmable

- simple and fast material change

- Adjustable height and system rotation can be adapted to any packaging operation

- possibility to remove fillings directly from the system or produce them into the storage tank

- fillings can be one- or two-layer

- different paper weights (72 g/m2 for heavier products, 92 g/m2 for the heaviest products)

Air films, pads and bags

Air films, pads or bags are very effective packaging agents with a number of advantages.

Their use is fast, variable and very effective. They save storage space. And they are also very ecological, since the main material of these packages is air.

Fill-Air® RocketTM - air cushion system

By means of a special Fill-Air® RocketTM machine, the customer produces air cushions in required sizes from the endless PE film. These cushions are inserted into the void space around the product being packed in the box. The air cushions prevent product movements in the carton and ensure its safe transportation. The system allows for storing large amounts of packaging materials without high requirements for storage space.

By means of a special Fill-Air® RocketTM machine, the customer produces air cushions in required sizes from the endless PE film. These cushions are inserted into the void space around the product being packed in the box. The air cushions prevent product movements in the carton and ensure its safe transportation. The system allows for storing large amounts of packaging materials without high requirements for storage space.

- 30 meters of inflated cushions per minute

- quick start

- sensors in the identification of cross-connection

- automatic position control

- automatic addition sensor

- patented edge weld technology with ambient temperature detection

- silent mode option

Cushion sizes:

The Fill-Air® RocketTM system is available in three different widths (200 mm, 250 mm and 300 mm) and can be adapted to two different lengths of filling (130 mm and 200 mm), which creates the possibility of six different sizes of filler.

Foils can be clear or with a proportion of recycled material (min. 50%).

Check out the video of the packaging using the Fill-Air system.

NewAir I.B.TM Express System - a system for creating XXL bubble wrap

A fast system for serving packaging stations with a high packaging material turnover that allows for storing large amounts of packaging materials without high requirements for storage space.

A fast system for serving packaging stations with a high packaging material turnover that allows for storing large amounts of packaging materials without high requirements for storage space.

Bubble foil (the height of bubbles 13, 19 or 25 mm) is highly resistant to pressure and impact and protects goods very efficiently, e.g. during transportation.

System Specification:

- machine weight without a roll: 36.7 kg

- machine dimensions: length: 77 cm, width: 67 cm, height: 46 cm

- easy operation

- can be winded automatically on a roll and delivered to the place of application

Check out the video on the NewAir system .

Bubble Wrap®

This universal inflatable system can use more than 80 types of foils for the production of bubble wrap, air cushions or bags.

Intelligent system technology automatically detects and configures the machine to the correct sealing temperature, airflow and pressure based on the inserted material – no programming or training required. It's simple and easy.

The Bubble Wrap system produces fillings at speeds of up to 24 m/s. It will produce enough fillings even for large e-shops. Various system mounting options allow you to create a more efficient packaging workplace and save space – table, wall or floor stands with retractor are available.

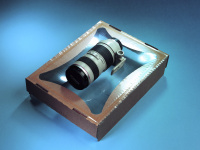

KORRVU Fixing Membranes

The Korrvu system consists of a cardboard body and a film of a high stretchability that is applied to the cardboard by means of a special adhesive. The fragile product is safely fixed by the film - anti-slide elastic membrane - straight in the cardboard box. It is protected against impacts this way. The system provides the protection of the product during the whole shipping, distributing, and handling process. The transparency of the Korrvu membrane allows for undistorted and coloured view of every product.

Korrvu Fixing Membrane application

- packaging of computer components, lamps, headlights, spare parts for the automobile industry, surgical and medical instruments, bicycle components, electronics, printed circuit boards, telephone and telegraphic equipment, drugs, etc

- this material is applicable wherever a high packaging standard in respect of safety and design is required

The Korrvu system is also supplied with corrosion protection for products in danger of corrosion. The Korrvu membrane also contains corrosion inhibitors that form a protective layer around the product and protect it against corrosion.

Check out the video on the Korrvu system.

Rapid Fill® - automated filling of voids in a cardboard box

Prevents the movement of products in a cardboard box. The Rapid Fill® system uses less  material than during normal packaging because there is no waste - the main filling is the air. The main benefit of the system is to streamline the packaging process with minimal demands on the number of packaging workers - Rapid Fill® system saves packaging labour costs.

material than during normal packaging because there is no waste - the main filling is the air. The main benefit of the system is to streamline the packaging process with minimal demands on the number of packaging workers - Rapid Fill® system saves packaging labour costs.

- dramatically increased productivity - can fill up to 8 - 12 cardboard boxes per minute, compared to 1-3 packages per minute when using manual methods

- economy - the system saves labour costs

- excellent product protection - this system wraps your product so that it is perfectly fixed and protected

- easy to use - the operator inserts the Rapid Fill® bag into the box and the Rapid Fill® system will do the rest

Check out the video on the Rapid Fill system.

Send your inquiry to demand@tart.cz or call at +420 548 210 500.