Instapak® polyurethane foam is great protection for your products. The polyurethane foam is injected into special bags, where the solidification increases its volume, flows around the product and fills the free space in the cardboard box in which the product is stored. INSTAPAK Foams are divided by density and method of application.

Instapak Foam Filling

Packing in INSTAPAK® polyurethane foam

- secure method of protective packaging of products against vibrations and shocks during handling and transport (preferably used in cardboard boxes)

- minimum material consumption

- used in the packaging of glass, porcelain, fine-art objects, antiques, musical instruments, sanitary ware, computers, sensitive appliances, furniture, and sets of fragile goods

Check out the video of Instapak foam packaging.

Principle of packing in Instapak® polyurethane foam

- PUR foam (component A and B) injected into special bags during solidification (that occurs when the components are mixed) increases in volume, flows around the product and fills the void space in the cardboard box in which the product is inserted

- Instapak® polyurethane foam will increase its volume after application by up to 280 times the volume of the original liquid

- foam stored in two 210 litre barrels is equivalent to the volume of storage space of a truck

- Instapak® polyurethane foam guarantees the creation of perfect fillings with various shapes for a wide range of products.

- customer receives the product undamaged during transport and handling, professionally packed in a light weight package

- created fittings are then reusable (the product can be unloaded and inserted)

Advantages of packaging in Instapak polyurethane foam:

Advantages of packaging in Instapak polyurethane foam:

- economical packaging method, which dramatically reduces the costs of packaging materials,

- easy and safe operation with high packaging productivity

- impact-resistant packaging for small, large, fragile or heavy products

- ease and speed of application

- low costs of storage and transport of containers before use

- lightweight packaging

- possibility of reuse

- recyclability

USED INSTAPAK® FOAMS:

Instapak foams are of several types which differ from each other mainly in gravity (density) and flexibility:

Instafill

• specific gravity of 6 kg/m3 (when stuffed with lighter foam of 8 kg/m3)

• production of fittings (made in TART, both with manual system and the SpeedyPacker system)

• highest flexibility

Moulding

Moulding

• specific gravity of 10-11 kg/m3 (depending on flexibility)

• production of fittings (made in TART, both with manual system and the SpeedyPacker system)

• less flexible

G-Flex

• specific gravity of 22 kg/m3 (comparable to polystyrene)

• the least flexible

• production of fittings (made in TART, both with manual system and the SpeedyPacker system)

Rigid

• specific gravity of 23 kg/m3

• nonflexible

Instafill Slow rice

• we do not sell it, but we can offer storage of foams

• the size of the barrels are either 60 l or 210 l (only G-Flex does not have 60 l barrels)

• highest flexibility

Instapak® foam application options

Instapak® foam fittings can be used for individual products, both the large and small series. Individual numbers of pieces have specific methods of application. The larger the series of products, the lower the cost of packing.

Instapak QUICK - foam bags for individual products

InstapakSimple - a simple system for creating pads for the smaller series

Instapak 901 - foam application using a gun. For larger applications (foil width up to 120 cm)

Instapak Tabletop - a simple system for creating pads for the medium series

Instapak Complete - a system for creating an endless series of foam tubes (with adjustable perforation) for the medium and large series

Speedy Packer - a system for the creation of pads and fittings from a mould for the larger series

Pre-formed Instapak fittings – TART also supplies its customers with ready-made fittings (of forms) according to their needs

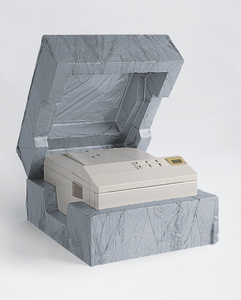

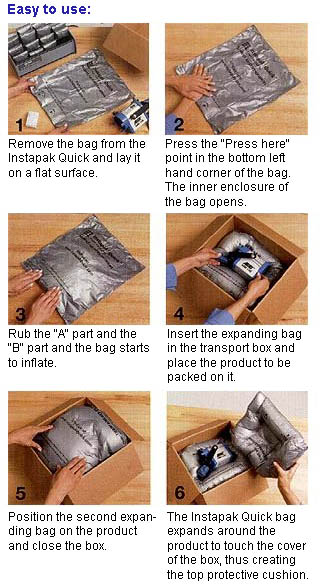

Instapak® QUICK

Instapak Quick is an economic method of the packaging into foam bags in a convenient compact system.

Packaging into the Instapak Quick foam cushions is suited for companies that wish to use the excellent filling properties of Instapak foam without the necessity of initial investment. One small box of the Instapak Quick foam contains protective cushions for 24 boxes. Products are protected safely and the company saves valuable working space.

Packaging into the Instapak Quick foam cushions is suited for companies that wish to use the excellent filling properties of Instapak foam without the necessity of initial investment. One small box of the Instapak Quick foam contains protective cushions for 24 boxes. Products are protected safely and the company saves valuable working space.

Main benefits:

- economical and effective protection of products of almost any size, shape and weight

- foam expands in several seconds and creates protective customized cushions

- anyone can become a packaging expert in several minutes

- Instapak Quick expands to a volume 200 times the volume of the original liquid

Environmental Profile:

- maximum protection reached with a minimum amount of material used. Less packaging materials means less waste

- disposable together with ordinary waste or reusable as void filling

- compressed waste takes up about 10% of its initial volume

- it is manufactured without chlorofluorocarbons and hydrogenated fluorocarbons

INSTAPAK® SimpleTM

Instapak® SimpleTM is a foam platform in a bag and is currently the easiest application. It combines excellent performance of Instapak® foam packaging and delivery system according to the requirements, which requires minimal training and service.

Instapak® SimpleTM is a foam platform in a bag and is currently the easiest application. It combines excellent performance of Instapak® foam packaging and delivery system according to the requirements, which requires minimal training and service.

Main benefits:

- versatility - suitable for packaging a wide range of products

- immediate formation - foam is formed at the point of use, which ensures the use of the correct amount of material each time

- protection of products - excellent cushioning ability to ensure maximum protection with minimal amounts of material

- space saving - saving valuable storage space

- minimum investments - foam ingredients are supplied in containers which are easy to handle, which reduces the need to purchase and store bulky packaging materials

- reduced volume and recycling - immediately forming foam in the bag prevents excessive volume of packaging, bottles with components can be recycled with ordinary plastic waste to ensure easy and responsible disposal

Check out the Instapak Simple video.

Instapak 901 - Handheld Systems

Instapak 901 - Handheld Systems

The simplest device for the production of polyurethane foam is produced by a handheld gun and is suitable for packaging products in the small series or production of fittings (also in the small series).

Classification of manual packaging system

- Manual system for 60 l barrels

- System for 210 l barrels

Foils for manual systems

- width of 60 cm, 90 cm, 120 cm

- each of the rolls are 1440 m2

Tabletop

-

simple system for the manufacturing of polyurethane foam injected into bags

simple system for the manufacturing of polyurethane foam injected into bags - intermediate stage between the manual system and SpeedyPacker, but compared to SpeedyPacker it is not possible to set bag sizes.

- Foils for TableTop (ITT Foil) - width 47cm, length 550m, perforated to 40cm or 60cm

Check out the Instapak Tabletop video.

Instapak Complete

-

Instapak Complete ™ system creates continuous foam tubes and foam-filled bags. The system allows for the production of variable bags (depending on the foil) or an endless belt of foam tubes with adjustable perforation.

Instapak Complete ™ system creates continuous foam tubes and foam-filled bags. The system allows for the production of variable bags (depending on the foil) or an endless belt of foam tubes with adjustable perforation. - diameter of the tubes may range from 2.5 cm to 12.5 cm

- The system can be retrofitted with a reservoir and produce fills for later use or to supply several workplaces

- Instapak Complete is the perfect solution for any size packaging operation

Check out the Instapak Complete video.

SpeedyPackerTM

-

this device manufactures bags with injected mixed polyurethane foam

this device manufactures bags with injected mixed polyurethane foam - possibility to select 6 customized bags that are stored in memory and can be easily changed

- suitable for packaging directly (bags), as well as for the manufacturing of fittings (by adding a device for the production from moulds)

- maximum speed - up to 21 bags per minute

- Foils for SpeedyPacker (SP foil) - width of 30 cm or 47 cm (Flat) - without double fold, or 47/7 cm - with double fold.

Check out the SpeedyPacker video.

Pre-formed Instapak fittings

The easiest way to use Instapak foam fittings are the supplies of finished packages directly from TART. The customer does not need any system (no investment costs) and receives the required packages in the preferred quantity and time.

Your inquiries or questions should be sent to poptavky@tart.cz or call +421 548 210 500.