Polyolefin heat shrinkable foils Cryovac and OPTI provide a unique appearance of the packaged goods. Due to their exceptional strength, elasticity and shape memory effect they are suitable for protection and packaging of grouped products.

Polyolefin Foils

Cryovac HEAT-SHRINKABLE FOILS

- made of several concurrently extruded layers of 100% polyolefin,

- packaging of non-food and food products,

- foil can be equipped with the recycling symbol or custom-printed.

All types of foil are suitable for manual packaging and packaging on semi-automatic and automatic machines.

Characteristics of Cryovac heat-shrinkable foil:

- cross-linked molecular structure, which makes it possible to produce an ultra thin foil with excellent resistance to wear

- unique manufacturing procedure extends shelf life of packaged goods and preserves aroma and flavour primarily in food products

- packaging in ultra-thin foil means material savings, minimum waste, easy recycling and disposal without endangering the environment

Advantages of Cryovac foil:

- gloss, clarity, transparency,

- flexibility, resistance to damage and rupture,

- strength of welds,

- adaptability for a wide range of shapes and sizes,

- the foil has anti-mist properties to prevent vapour condensation inside the packaging – the foil remains constantly clear

Examples of the use of packaging:

- household goods and appliances

- books, CDs, toys

- paper, textiles

- cosmetics

- food

| Use | Type | Product | Thickness (µm) |

Roll width (mm) | Winding length (m) |

| Soft products (PVC replacement) | D-940E | semi-tube | 19 | 205-855 | 1067 |

| 15 | 1332 | ||||

| 11 | 1777 |

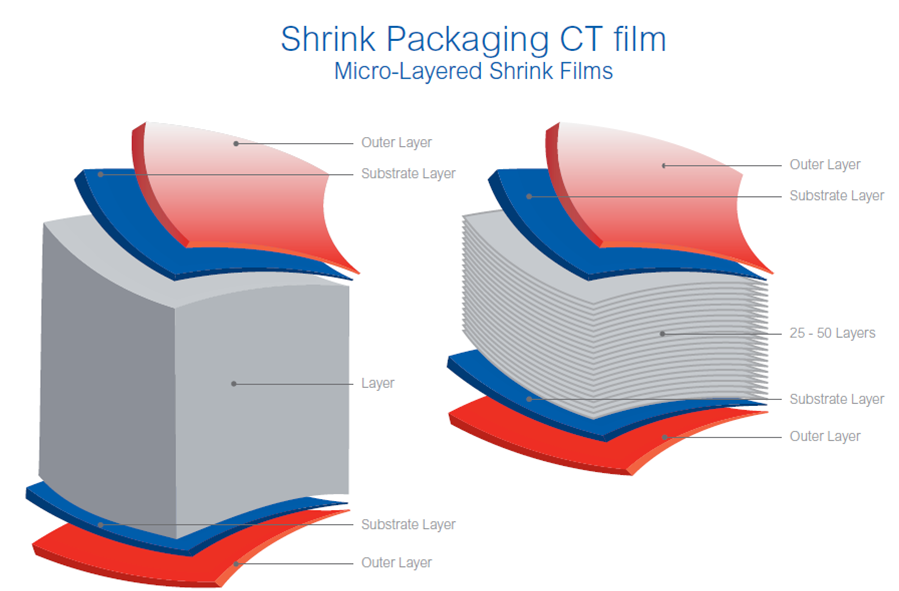

Cryovac® CT foil

New Cryovac® CT foils are versatile polyolefin films for packaging. The unique properties of these foils are achieved by mikrovrstvení technology. Unlike conventional 1-, 3- or 5-layer foils, the Cryovac® CT foils have 25 - 50 separate microlayers. The ability to create a high number of layers allows a significant increase in the mechanical resistance of the foil while improving workability compared to often much thicker foils, which are produced by conventional technologies. Greater resistance means more weight saving on packaging per packaged unit.

Cryovac® CT foil won the award “Package of the Year 2013”.

Advantages:

- up to 50% packaging material saving

- excellent optical properties - perfect clarity and reduced cloudiness

- excellent workability

- lower costs of transport and storage

- less frequent exchange of roles on packaging lines

- environmentally friendly solution

|

Product |

Thickness (µm) |

Type |

Width (mm) |

Reel (m) |

|

Cryovac® CT-301F |

7 |

semitube |

155 - 955 |

2667 |

|

Cryovac® CT -302E |

9 |

flat |

100 - 1610 |

4300 |

|

Cryovac® CT -302E |

9 |

semitube |

155 - 955 |

2150 |

|

Cryovac® CT -303E |

11 |

semitube |

155 - 1005 |

1905 |

|

Cryovac® CT -304E |

14 |

semitube |

155 - 1005 |

1454 |

|

Cryovac® CT -305E |

17 |

semitube |

155 - 1055 |

1143 |

|

Cryovac® CT -306E |

23 |

semitube |

155 - 1055 |

885 |

|

Cryovac® CT -308E |

38 |

semitube |

155 - 905 |

533 |

Send your inquiry to demand@tart.cz