Sustainable development

We take sustainable development seriously

We preserve nature for future generations! For us, environmental protection is not just a phrase, but a real goal. Therefore, we use many different ways to reduce our carbon footprint and all other possible impact on nature.

Research and Development

Our arms are wide open for innovation. We develop not only new recipes and production processes but also new packaging designs. All in order to minimise the environmental impact of the packaging. Therefore, we reduce the amount of material used for product packaging, use the largest possible share of recycled raw materials and minimise the share of plastics in packaging by replacing them with materials from renewable resources. For example, we produce PE foils that are the same strength but half the thickness. The same is true for our BUFO barrier bubble wrap, which consists of several microlayers and lasts longer than conventional double weight bubble wrap.

Sophisticated logistics

One vehicle, several shipments. Transportation has a big impact on the carbon footprint so we try to make it as efficient as possible. Therefore, we reduce the negative impacts of transport on the environment with carefully thought-out logistics.

Returnable packaging system

No unnecessary waste. We produce reusable packaging that will last for many months and years. In addition, they are easy to fold and, thanks to this, take up much less space in distribution vehicles.

Recycling

All our packaging is fully recyclable. After their use, another product is made from them. A lot of packaging can also be made from used material, which is usually more environmentally friendly than using the primary raw material. For some, a secondary raw material is even necessary. This applies to ordinary corrugated cardboard boxes or moulded pulp packaging. However, there is a lot more packaging that may contain a proportion of secondary raw materials - wrapping paper, ordinary foil, bubble wrap, binding tapes, polystyrene and more. At TART we use a lot of secondary raw materials. We process over 400 tons of waste paper and plastic waste per year for the production of our packaging. We have also launched our very special range of recycled packaging under the ReProtect brand.

Compostable packaging

They have grown in the field and will return to the field. We produce Envira organic packaging purely from potato or corn waste starches. They also have better appearance and mechanical properties than polyethylene materials. And once they fulfil their purpose, microplastics do not contaminate nature. The bacteria ensure that they break down in the compost into pure biomass, which serves as fertiliser for other crops.

Reusable packaging

The best waste is no waste. As a result, reusable packaging is more environmentally friendly than disposable packaging. Returnable packaging can be made for a closed circuit, where the manufacturer packs the goods and sends it within the logistics chain. There the goods are unpacked and empty packaging sent back. This type of packaging is widely used in the automotive industry, but it can also be used, for example, in internal logistics within one company.

Optimisation

Our experience shows that the right packaging not only reduces the company's costs, but also minimises the negative impact on the environment. And what is the right packaging? There are a number of possibilities. For example, modern multilayer films can be used because they are much stronger than conventional single-layer films, therefore they can be thinner and so fewer are needed for packaging. Another option is a box with cushioning inserts that sufficiently protects the packaged product but takes up as little space as possible and thus reduces logistics costs. Wooden pallets can also be replaced by moulded pulp packaging. Or why not use MilCorr shrink wrap instead of a wooden box. Only a few types of packages cannot be made more efficient.

Packaging automation

Experience shows that using packaging machines and lines can significantly save packaging material compared to manual packing. When pallets are wrapped in stretch foil by a machine, there is a saving of more than half of foil compared to being packed by hand. Cardboard glueing machines are also economical. And in general, all packaging machines significantly save labour costs. In the end, it is also more ecological.

Certification

The certificates that our company has received prove that we are really serious about sustainable development:

Eco Vadis - Social responsibility

As part of its social responsibility, TART, s.r.o. has integrated social and environmental considerations into its processes and takes into account the needs of its customers, suppliers, employees and other stakeholders affected by its activities. The company also emphasises minimising the negative impacts of its activities on the environment. It perceives its social responsibility as a complex issue that touches on a wide range of aspects - economic, social and environmental.

TART is evaluated by the independent multinational company EcoVadis, which strictly audits established processes and measures. TART has been given EvoVadis award and is able to make the overall results of the audit available to its business partners.

The company is constantly working to improve processes based on feedback from the EcoVadis audit, the requirements of its customers and other external and internal suggestions.

FSC® (Forest Stewardship Council®)

TART is FSC® certified (FSC-C164009). Through the certification of the processing chain, it guarantees that the selected end products come from FSC®-certified forests, which means that every processor and trader in the processing chain, from the forest to the producer of the final product, must obtain FSC® certification. This gives the customer the certainty that he is buying a product from sustainably managed forests.

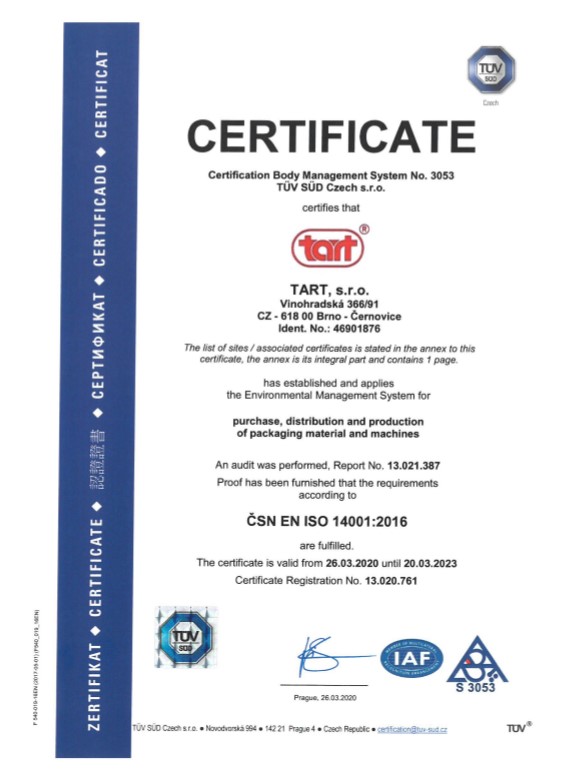

ISO 14001

TART is also certified according to the ISO 14001 standard, which forms an environmental management system. We are constantly reducing the negative impact of all the company's activities on the environment, looking for better use of our resources and eliminating waste.